DPF / FAP filters and SCR catalysts cleaning technology.

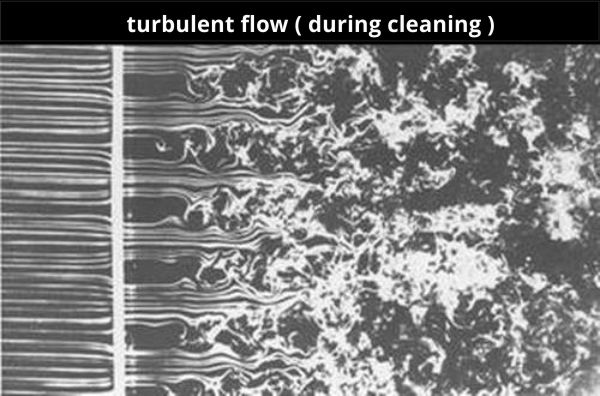

Our hot-water high-pressure devices use the power of turbulent water hydrodynamics (Fig.1) and the force of the compressed air pulse from the compressor. The movement of the liquid (working fluid) is forced by the external pressure which must overcome the flow resistance in the filter channels. At turbulent flow, streams of liquid mix to form whirls that easily penetrate and remove solid particles in the microporous septum of the filter channels.

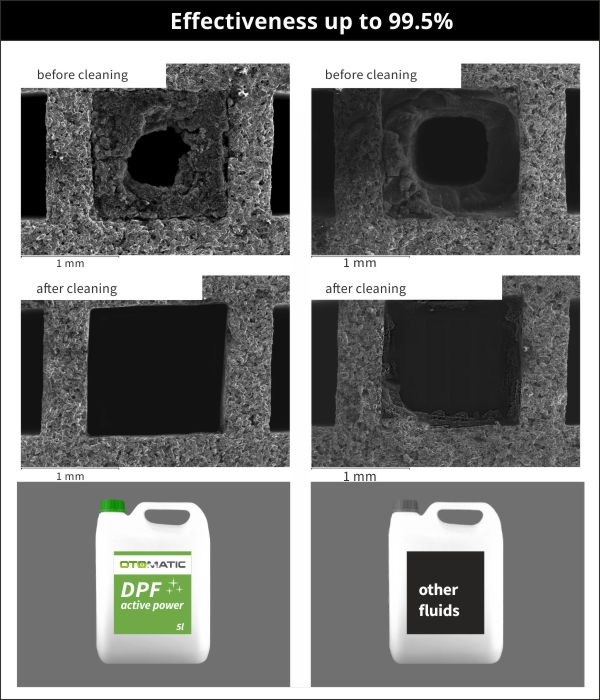

Our devices work perfectly with DPF Active Matic liquid reducing the surface tension of water, thanks to which the particles of the cleaning agent are easier to combine with the dirt particles, and the more effectively they detach them from the surface being cleaned.

DPF Active Matic read more...

During cleaning, the flow geometry of the DPF filter provides resistance with the simultaneous creation of high velocity flow and high shear stress, which is the main mechanism for removing compressed deposits in the filter channels.

In addition, the flow resistance is caused by the appropriate viscosity of the detergent (DPF Active Matic), which causes that during the movement of liquid molecules, a phenomenon similar in effect to friction occurs.

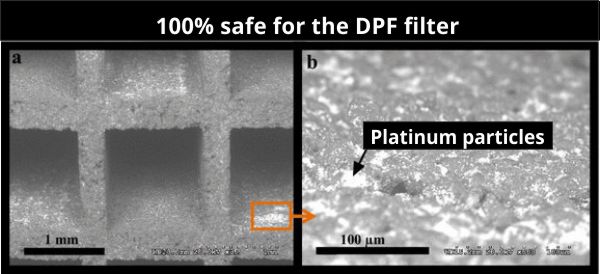

The method allows for very precise removal of all types of solid particles (soot, ash, oils) from both the outlet and inlet passages of the filter.

The technology includes:

The technology includes:

Cleaning process:

Advantages of the method:

Advantages of the method: