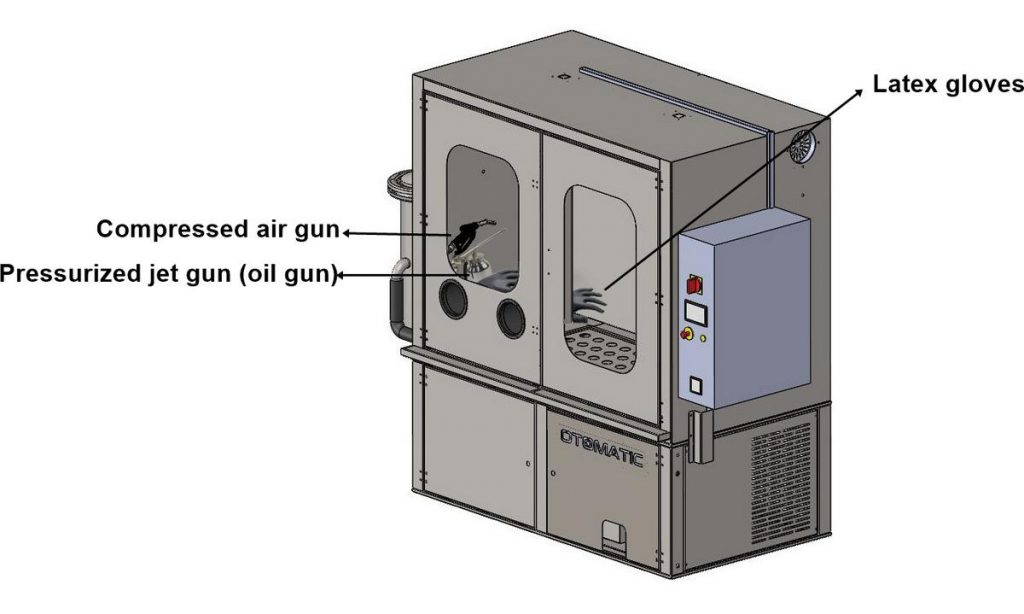

The oil separator is used to collect oil floating on the surface of water. It can be used wherever the work surface is small and where liquids need to move and be deoiled at various locations. Often, oil-soaked particulate filters precipitate into the wash after turbocharger failures. Previously, no de-oiling systems were used in DPF cleaning machines, and floating oil suspensions had to be removed manually.

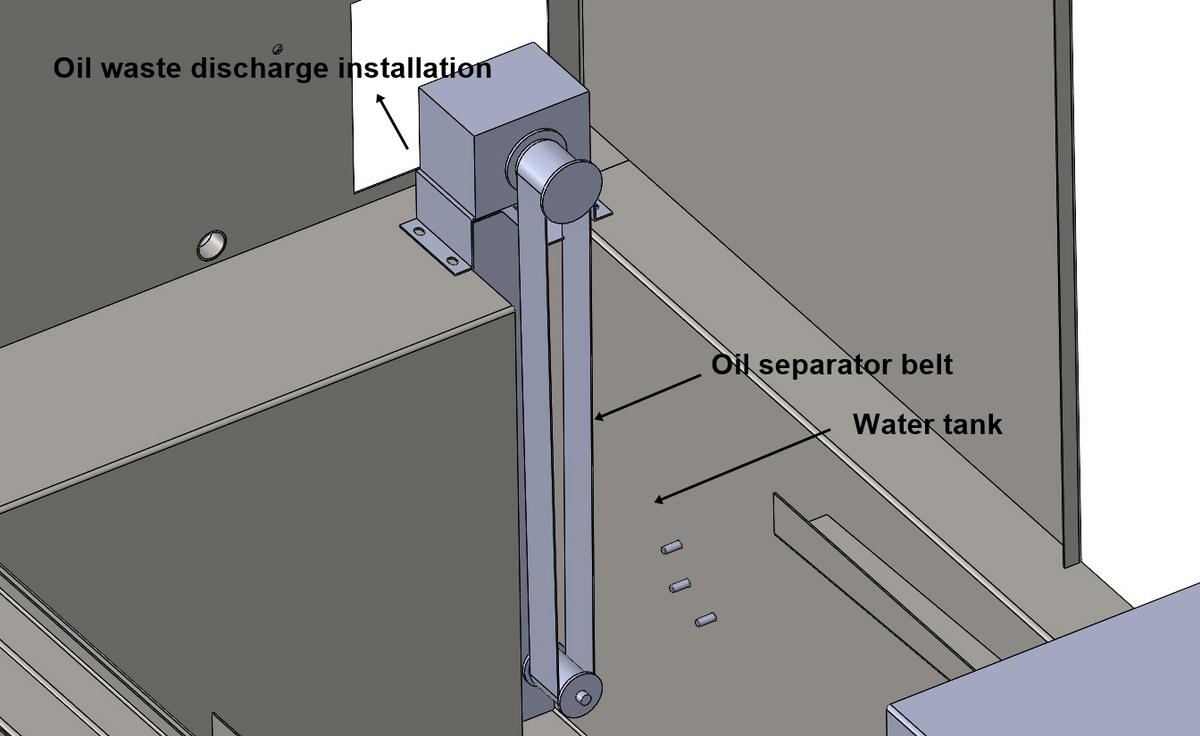

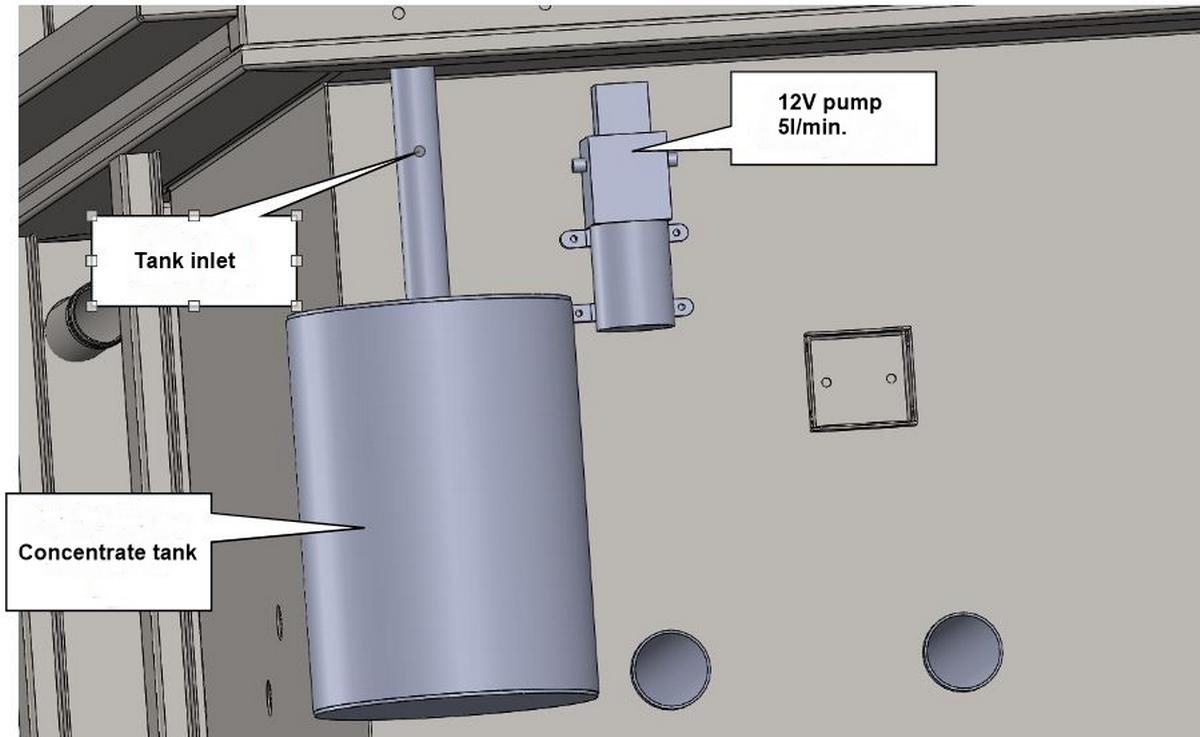

Unfortunately, this was not comfortable for the machine operator and, importantly, did not produce the desired results. Nowadays, thanks to the belt oil separator which is installed in the left rear corner of the water tank on the DPF Premium machine, separating oil from the working fluid is no problem and takes place automatically. The tape is made of plastic with adhesive properties.

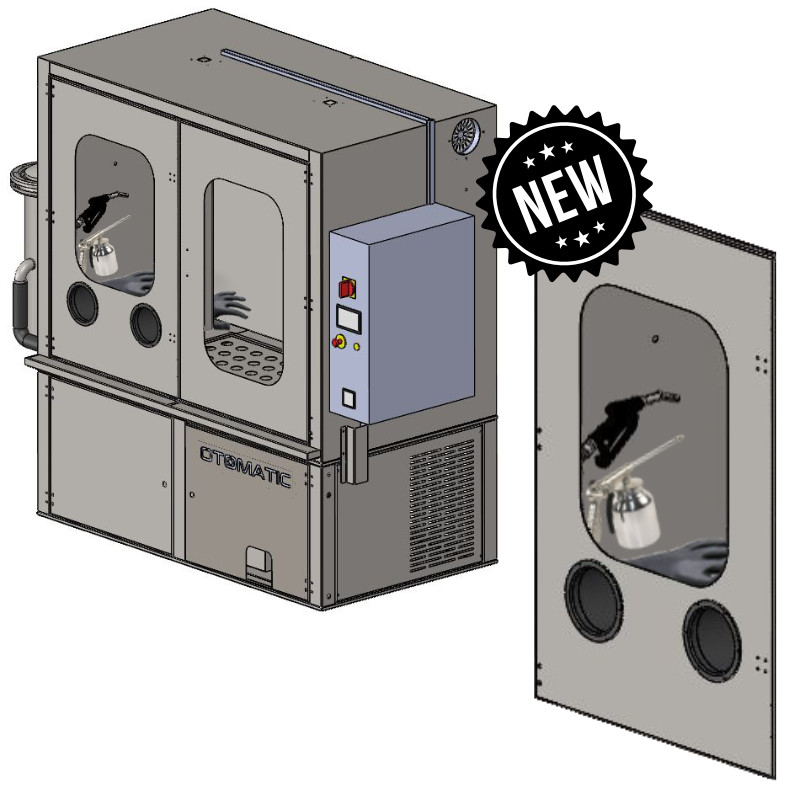

This makes it easy to separate the oil from the working fluid. The waste removal system from the oil separator is located outside, on the left side of the machine. In order to collect unwanted substances, simply place a 5-liter container, e.g. a can, under the outlet. The biggest advantage of using a belt oiler is its high efficiency, regardless of the water level in the tank. In addition, it extends the service life of process equipment while reducing operating costs. It is also possible to equip DPF Premium machines with an oil separator at an additional fee.